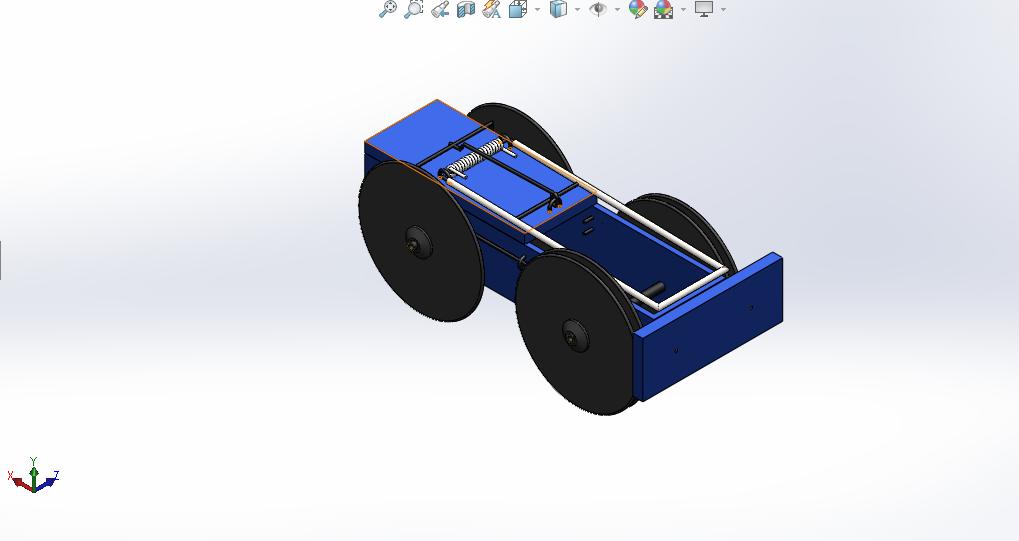

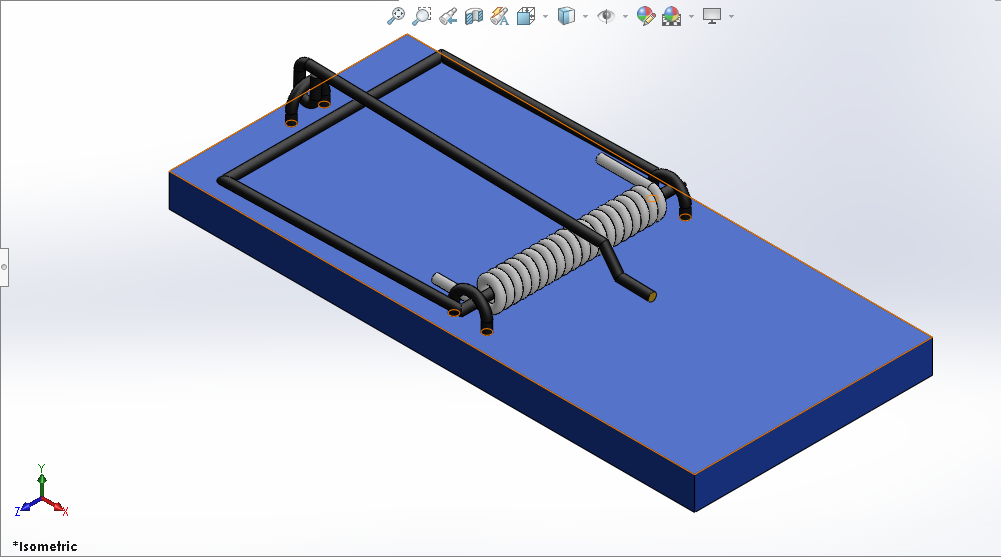

Here is a custom design of an optimized high-performance mouse trap car. Engineering drawings created in Solid-works showcase the intricate component pieces that can be manufactured in-house using 3D printing technology. This includes specialty plastic wheels with precision ball bearings to minimize rotational friction at the axles, as well as a complex trigger mechanism that employs a U-shaped wire, catch, latch and other custom parts to maximize the power stroke from the high-tension spring. The modular plastic body comprises an aerodynamic wedge shape and integrates two mouse traps with gears to distribute torque to both front and rear axles simultaneously. Detail and assembly drawings provide clear exploded views of the simple yet effective construction based on interlocking snap-fits requiring no tools. Videos demonstrate the operation of the acceleration and release mechanism and display the car traversing a 15-degree downhill test track, where performance can be fine-tuned by adjustments to the center of gravity location.